Capabilities

We can get the job done. PCC Aerostructures offers customized solutions to fit projects large and small.

PCC Aerostructures includes a large group of sites that offer world-class aerospace assemblies and components.

Machined components range from simple 3-axis aluminum parts to complex, close-tolerance, hard metal parts machined on 5-axis CNC mills.

Core specialties include complex milling and turning of aluminum, titanium, stainless steels, high heat-treated steels, Inconel, and other hard alloys, with additional expertise in high-speed machining of titanium.

Extensive sheet metal capability, metal bonding and composite manufacture and repair, and metal finishing complete our structural component and detail capability.

Assembly capabilities range from flap support assemblies to main cabin entry doors on many aircraft platforms.

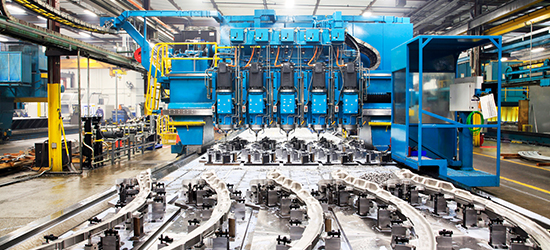

Precision Machining

Come to PCC Aerostructures for world-class for complex machining, both large and small.

Super Kits

Our goal is to use unique capabilities to redefine and enlarge your work packages to save you time and cost.

Metal Finishing

Full-service finishing capabilities: eco-friendly coatings, FAA approved repair, light benchtop assembly.

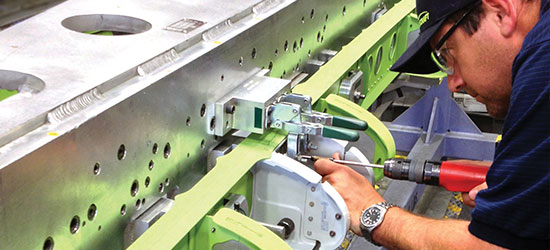

Complex Assemblies

One of the largest build-to-print manufacturers of complex structural and mechanical assemblies.

Sheet Metal

From simple to highly complex formed parts and assemblies, we are your sheet metal source.