Noranco was accquired by Precision Castparts Corp. in October 2015.

Noranco Sites Include:

Deer Valley

1620 West Knudsen Dr.

Phoenix, AZ

623-582-2261

Jet Processing

2632 W. Quail Ave.

Phoenix, AZ

623-869-6749

Monterrey

Ave TLC 150, Parque Inds.

Stiva Aeropuerto

Nuevo Leon, MX

Pickering

1842 Clements Rd.

Pickering, Ontario

905-831-0100

Vaughan (Consolidated into Woodbridge)

55A Westcreek Dr.

Vaughan, Ontario

905-856-1801

Woodbridge

710 Rowntree Dairy Rd.

Woodbridge, Ontario

905-264-2050

Capabilities

Our core products include Aerostructure, Landing Gear and Aero Engine precision components and complex assemblies.

We provide value to our customers through a wide range of sophisticated capabilities including high precision machining and sheet metal fabrication, processing, assembly, testing and supply chain management.

Our 300+ CNC machine centers and 40 years of experience enable us to offer one-stop shopping for any complex component or sub assembly. Noranco's ownership in two special processing operations ensures access to metal finishing capacity and capabilities such as; shot peen, HVOF, chrome, cad and anodize plating.

Noranco has more than 1000 employees across 8 manufacturing sites in Canada, the United States and Mexico, making us one of the largest Tier 2 / Tier 1 aerospace companies in Canada.

Manufacturing Capabilities

- CNC Machining

- CNC Sheet Metal Fabrication

- Precision Grinding and Honing

- Welding

- Assembly

- Hot Joggling

- Hydraulic Actuator Assembly and Testing (Skydrol)

- Mechanical Testing

- Kitting

- Finishing

Manufacturing Equipment

- 166 CNC Machining Centers

- 5 Axis Machines

- 4 Axis Horizontal Machines

- 3 Axis Vertical Machines

- Turning Centers (including Live Tooling)

- Integrex Multitasking Mill/Turn Lathes

- Grinders

- Honing Machines

- CNC Turret Punch Presses

- CNC Laser

- CNC Brakes

NADCAP Accredited

- Mig Welding – AWS D17.1

- Tig Welding – AWS D17.1

- Torch Brazing – AWS C3.4

- Anodize & Hard Anodize

- Grinding

- Shotpeen

- HVOF

- NDT

- Plating (Hard Chrome, CAD, Ti-CAD)

- Paint and Chemical Film MIL-C-5541, and MIL-DTL-5541

- Spot Welding of Aluminum, Steel, Stainless Steel – AMS-W-6858A

Manufacturing Systems

- Mastercam X4 – CAD/CAM

- CATIA Version 5 Release 20 – CAD/CAM

- Solidworks 2012 – CAD

- Lantec 26 – CAD/CAM sheet metal

- Vericut 7

Electronic File Acceptance

- Native CATIA

- STEP

- IGES

- DXF

Inspection Equipment

- Coordinate Measuring Machines (CATIA Interface capable)

- Faro Arms

Products

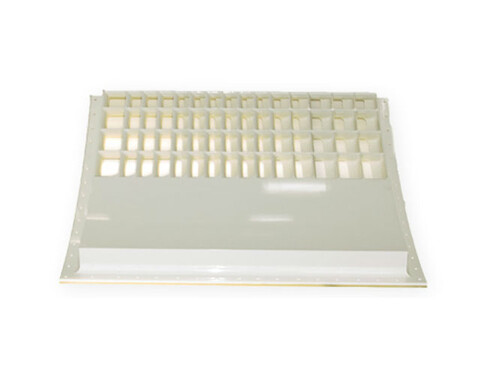

Avionics/Sheet Metal

Noranco Inc. has extensive experience working with all types of Aerospace sheet metals from Aluminum, Titanium, Stainless, Inconel, and Mumetal to Copper and Brass. Our integrated capabilities include forming, hot joggling, embossing and extrusion, MIG and TIG welding, torch brazing, soldering, and aerospace aluminum spot welding and assembly. Value engineering and integrated supply chain management are part of our core service offering.

Center Pedestal Assemblies

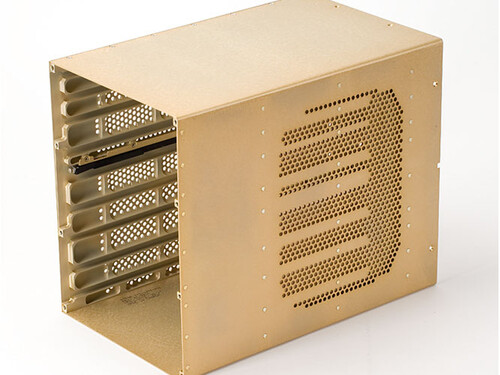

Circut Card Chassis

Flight Bag Supports

Aero Structures

Noranco Inc. aero structure capabilities include the manufacturing of complex 6 axis parts (Ti, Steel, AL) multi length stringers and air frame extrusions. Our world class forming and hot joggling are considered core competencies within the aero structure operations.

Landing Gear Yokes

Torque Arms

Trunnion Assemblies

Aero Engine Components

Noranco Deer Valley Division manufactures metalic structure in support of engine and auxillary power unit line replaceable units such as fuel pump housings, air intake manifolds, and engine casings.With close proximity to the Noranco Jet Processing Division, Noranco can supply integrated build-to-print solutions for both commercial and military applications.

Engine Valve Bodies

Machined Engine Bodies

Engine Ducts

Aircraft Sub-Assemblies

Noranco performs integrated manufacturing over a wide variety of sub-assembly work, from simple hardware installation and riveting to complex sheet metal and machined part assembly and testing. Noranco provides complex stringers to support critical wing box assemblies.

Engine Bypass Ducts

Fittings

Thrust Reversers

Landing Gear Systems

Noranco Inc specializes in the engineering support and manufacture of landing gear system components. Our capabilities include value engineering and precision manufacture of landing gear yokes, axles, actuators, cylinders, pistons and pins. We provide integrated and value added services in the areas of assembly, testing, multi-component kitting, and supply chain management.

Outstop Tubes

Landing Gear Pins

Landing Gear Braces

Approvals

- Airbus

- Boeing

- Boeing Mesa

- Bombardier

- Embraer

- GE Middle River

- Gulfstream

- Hawker/Beechcraft

- Israel Aircraft Industries (IAI)

- Latecoere

- Lockheed Martin

- Northrop

- Spirit Aerosystems

- United Launch Alliance

Customers

- Bell Helicopter

- Boeing

- Bombardier

- GE Avaiation

- Honeywell

- Lockheed Martin

- Northrop Grumman

- Parker

- Premium Aerotec

- SAAB

- SAFRAN

- Spirit Aerosystems

- Triumph Group, Inc.

- UTC Aerospace Systems

Supplier Quality Documents

| Title | Notes |

|---|---|

| Supplier Quality System Questionnaire | AQS1001 - Rev. B |

| Supplier Quality Requirements Manual | SQR-10000 - Rev. E |

| Corona - Purchase Order Quality Clauses | NORW-054 Rev. 5-2016 |

| Deer Valley - Purchase Order Quality Clauses | NORW-054 - Rev. 10/2/19 |

| Pickering - Purchase Order Quality Clauses | NORW-054 - Rev. C |

| Monterrey - Calibration Annex 1 | PQS-15-01 - Rev. I |

| Vaughan - Purchase Order Quality Clauses | NORW-054 - Rev. C |

| Woodbridge - Purchase Order Quality Clauses | NORW-054 - Rev. C |

| Monterrey - Purchase Order Quality Clauses | F-QS11-04 - Rev. M |

| Monterrey - Supplier Quality Assurance Requirements | Rev. 9/18/2018 |

Address:

1620 West Knudsen Dr

Phoenix, Arizona 85027

Phone: 623-582-2261

Fax: 623-582-2380

Sales Phone: 623-582-2261