About

Centra's culture has been built on a foundation of teamwork, technology and innovation. Through this foundation, it is building a sustainable, competitive organization.

- Centra's high-performance work culture is focused on continuously improving the way it does business.

- Centra's Continuous Improvement Tool Kit engages employees at all levels in a structured improvement journey.

- Centra's Mission as a company incorporates a view there must be a Win, Win, Win, (Shareholders, Employees, Business Partners) - each is dependent on each other.

- The key to its improvement strategy is the continued investment in leading-edge manufacturing and IT technologies.

Centra is committed to continuously developing its infrastructure of skill sets and capital equipment in order to support its customers ever-changing manufacturing environment.

Mission Statement Why We Exist

- Our Shareholders

- Our Employees and their Families

- Our Business Partners

Core Values What We Believe In

- Be passionate about being the best at what we do.

- Take pride in our successes; knowledge from our failures.

- Develop excellence in our people through knowledge, commitment and leadership.

- Reward excellence, counsel mediocrity and rid ourselves of negativity.

- Always be customer-focused.

- Conduct ourselves with integrity and fairness.

Vision What We Want to Be

- A great company to work with

- A great company to work for

- A formidable competitor

- A company that consistently grows value

Capabilities

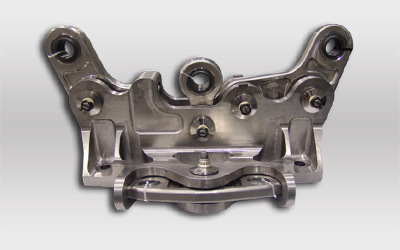

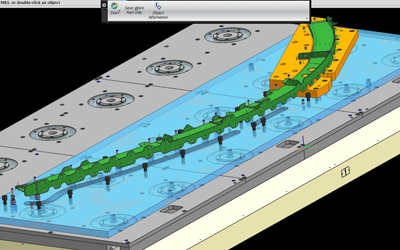

High Speed Machining (33,000 RPM)

- 3, 4, & 5-axis high speed machining of complex aluminum structures up to 13 ft (4m)

- 3, 4, & 5-axis machining of stainless steel grades, titanium grades, nickel-based alloys and machining at 50+ Rc - up to 80 in. (2m)

- Large Tool Change Capacity

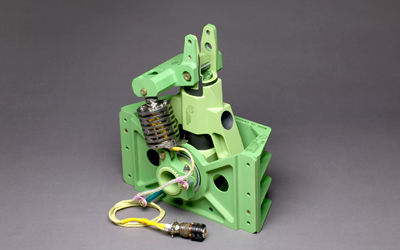

Assembly of Major Aircraft Sub-Structures

Metallic Assembly Core Competencies:

- Typical assemblies include multiple machined details, bearings, bushings, sheet metal components and miscellaneous hardware

- Takt driven, moving line assembly systems

- Monolithic and complex multi-component assemblies

- Adaptability to a wide range of components and production rates

- Assembly mechanic ownership for product quality

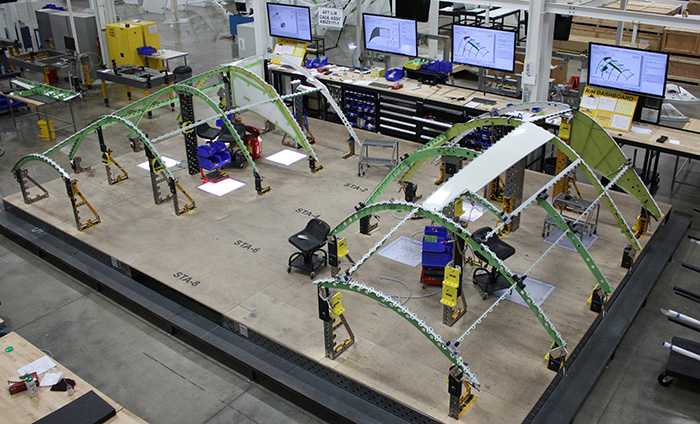

Structural Assembly Core Competencies:

- Robotic Nutplate Installation

- Robotic Teflon Application

- Large Floor Based Jig Assembly

- In-House Qualification of Final Acceptance Jigs (FAJ)

- Precise Part-to-Part Fit Requirements

- Assembly Mechanic Ownership for Product Quality

Engineering:

- Digital Model Based Certification

- Electronic Manufacturing Information Systems

Services

Centra is a global leader in Integrated Aerostructures through:

- Applying leading-edge machining technology.

- Utilizing Lean Systems and Manufacturing technologies in the development of its Assembly Processes.

- Leading in the development of information technology to simplify the complexity of its business.

- Providing consistent performance in the Quality, Delivery and Cost of its services.

- Being the Supplier of Choice when its customer is looking to develop or adopt a new initiative.

Level One

Aluminum Machining, Hard Metals Machining, Non-Core Systems & Items

- Aluminum Machining - Up to 12 feet (3.6 M) / Hard Metals Machining - Up to 80 inches (2 M).

- Complex Geometry.

- Tight Tolerance.

- Demands Technology.

- Non-Core Systems/Items - Supply Chain Competency.

Level Two

Metallic Assemblies, Structural Assemblies "Sub-Structures"

- Metallics are Key Cost Drivers.

- Pulses at Program Build Rate.

Level Three

Structural Assemblies "Sub-Structures"

- Complex Integration of Components.

- Large floor-based jig assembly systems.

Suppliers

Centra's procurement department is responsible for all aspects relating to supply chain development.

The department is responsible for:

- Developing a loyal, skilled and innovative supplier base to support its manufacturing and operational needs

- Assessing supplier capabilities to determine fit and growth opportunity

- Negotiating price and contract terms with suppliers

- Acting as a commodity-specific point of contact for supplier inquiries, status and projects

- Monitoring performance and rating of suppliers based on cost, quality, delivery & responsiveness

- Ensuring a competitive and high-performing supply base

What Does Centra Buy?

Centra buys services and materials to support production and operational needs.

- Subcontract machining services (metallic and non-metallic materials)

- Composite, sheet metal, formed and non-metallic components and hardware

- Raw material

- Component surface treatments

- Capital equipment

- Factory supplies and tooling

- Miscellaneous operational support, products and services

What Does Centra Look For in a Supplier?

- Cost, quality and schedule performance

- Commitment to continuous improvement and integration of technology

- Willingness and flexibility to grow with its business

- Commitment to customer service and the ability to provide innovative solutions

- Long-term partnership opportunities

Supplier Documents

Check our Supplier Documents for more supplier resources.

Supplier Quality Documents

| Title | Notes |

|---|---|

| Supplier Quality System Questionnaire | AQS1001 - Rev. B |

| Supplier Quality Requirements Manual | SQR-10000 - Rev. E |

| Centra Supplier Manual | Rev. H |

| Supplier Manual Acknowledgement Form | Rev. A |

| Supplier Quality System Audit | Rev. NC |

Address:

24 Cherry Blossom Road

Cambridge, ON N3H 4R7

Phone: (519) 650-2828