About

Aerospace Dynamics International, Inc. (ADI) is broadly recognized as one of the worlds’ most respected suppliers of large complex machined parts and assemblies to the aerospace industry.

Having recently achieved a Tier I status, ADI is a provider of major structural components on virtually every commercial and military aircraft program.

At every level, ADI's dedicated team has worked hard to achieve and maintain a world-class reputation for the highest level of excellence in quality, on time delivery, and customer service to exceed customer expectations.

With the rapid advancement in aircraft technologies, ADI continues to make sure we are able to meet our customers' current and future needs by constantly upgrading and improving our capabilities and facilities through the ongoing acquisition of the most technologically advanced equipment in the industry. Combined with a commitment to the continuing education and improvement of our workforce, and cutting-edge management systems, ADI is positioned to meet the challenges of the evolving needs of the aircraft industry.

ADI stands ready to offer the full depth of our combined resources to partner with our customers, from proposal through development, launch, and throughout the life of the program. We work hard to offer the most affordable and producible manufacturing solution to your most complex and challenging requirements.

ADI was acquired by Precision Castparts Corp. in March, 2014.

Capabilities

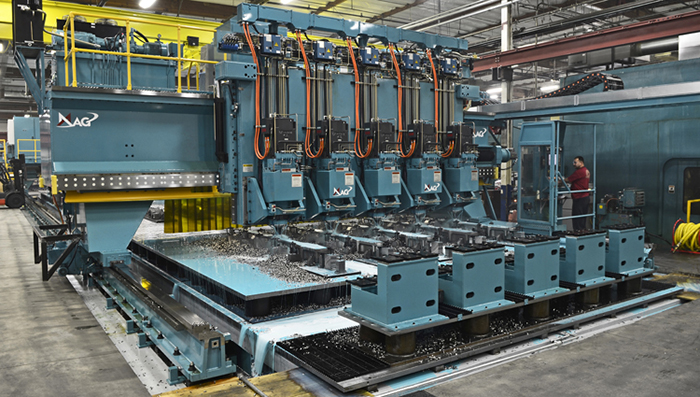

High Speed Machining

- 3, 4, 5 & 6 axis vertical & horizontal mills (multi-spindle 3 and 5 spindle set-ups)

- Kitting and complex assembly

- Single spindle configuration with gantry profilers up to 228 ft bed length

- Additional manufacturing space added with four state-of-the-art 5-axis, 5-spindle gantries installed on a 308 ft bed

Additional Capabilities

- 7 CMM machines

- Tooling design and fabrication, including cutters

- Titanium, hard metals and all series aluminum roughing and finishing

Hard Metal Machining

Structural Airframe

- Bulkheads

- Caps

- Fittings

- Longerons

- Stringers

- Floor Beams

- Stretch Forming

Skins & Panels

- Barrel Panels

- Wing Skins

- Fuselage Structural Webs

Multi-Spindle Machining

- Hard Metal

- Center Frames

- H Frames

- Spars

- Landing Gear Beams

- Pylons

- Wing Ribs

- Hinge / Latch Beams

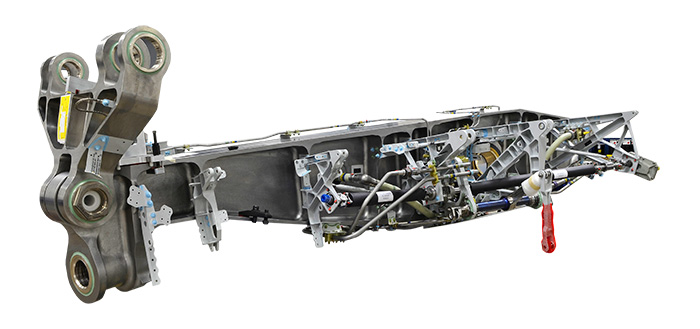

Assembly

Mechanical Assembly

- Sub-Assembly

- Metal Bonding/Welding

- Solid Rivet Installation

- Close Tolerance Bushing Installation

- Swage Bearings

Design and Development

- Structures

- Assemblies

- Hydraulics

Supplier Quality Documents

| Title | Notes |

|---|---|

| Supplier Quality System Questionnaire | AQS1001 - Rev. B |

| Supplier Quality Requirements | CP-002 - Rev. IR |

| Product Assurance Provisions | SP-03-01 - Rev. M |

| Airbus Maintained Specification Report | 74000001 - Rev. AS |

| Boeing/Spirit Maintained Specification Report | 74000002 - Rev. X |

| Lockheed Maintained Specification Report | 74000003 - Rev. J |

Address:

25540 Rye Canyon Road

Valencia, CA 91355

Phone: (661) 257-3535